The Crossing Vee

|

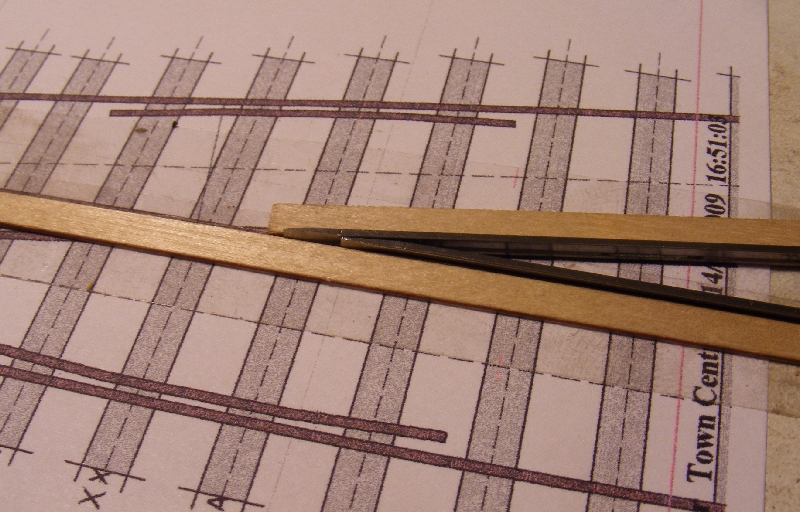

I

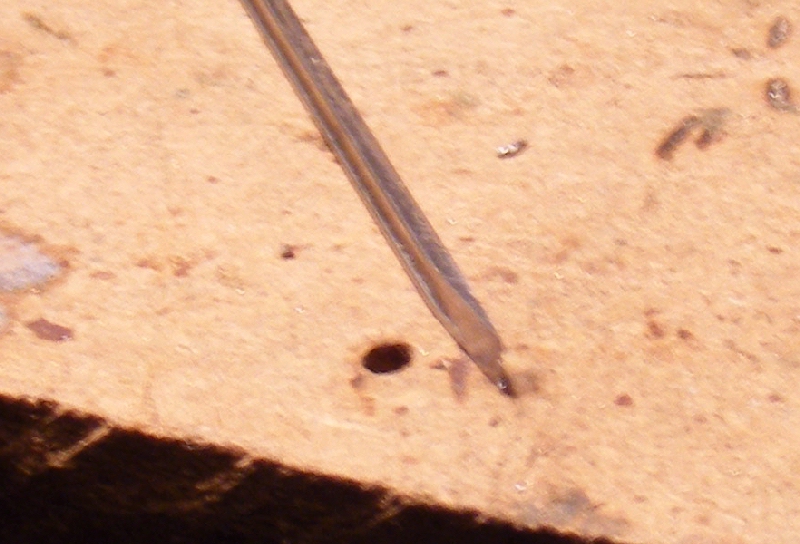

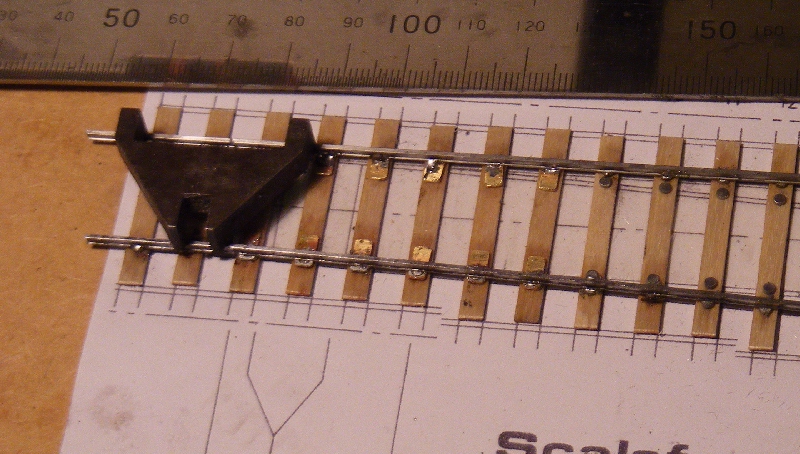

followed my normal practice of using two

offcuts of timbering to make a jig for the vees prior to fixing the

timbers in place to continue the construction. The jig is used

initially to check progress of the filing until the angle of the rail

end is a snug fit in the jig. The point and splice

rails are then soldered together upside down in this jig.

|

Filing the Vee

|

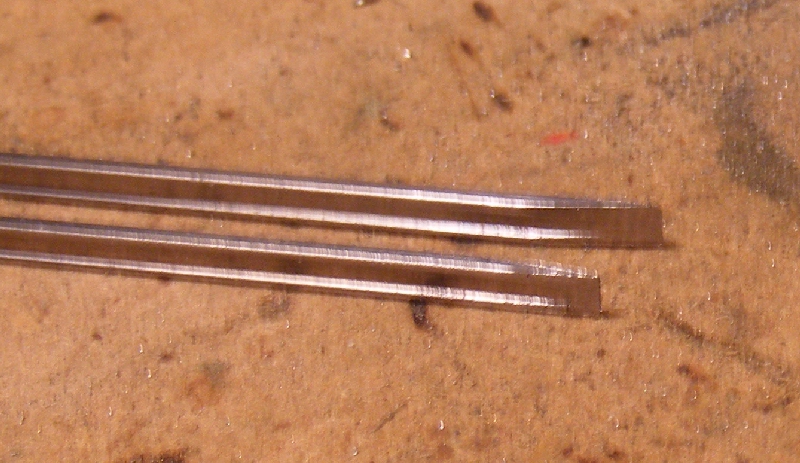

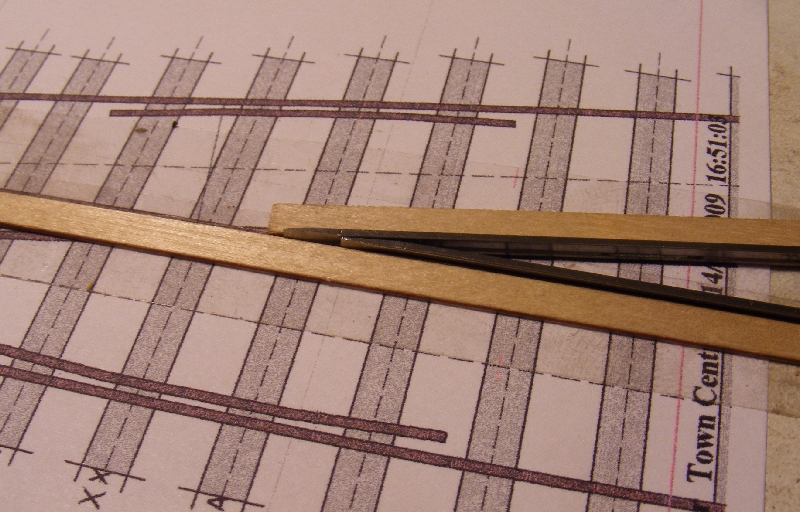

File

one side of the rail first until nicely into the web, then use a pair

of pliers to bend the rail so that the filed face is in a straight line

with the rest of the rail on that side.

Then complete the filing from the other side, marks on the filing board

6 times the rail width apart (for 1:6 crossings) will help gauge the

angle and it can be checked in the vee jig.

|

Make two such rails of opposite hands, so one can be used for the point rail, the other for the splice rail.

Assembling the Vee

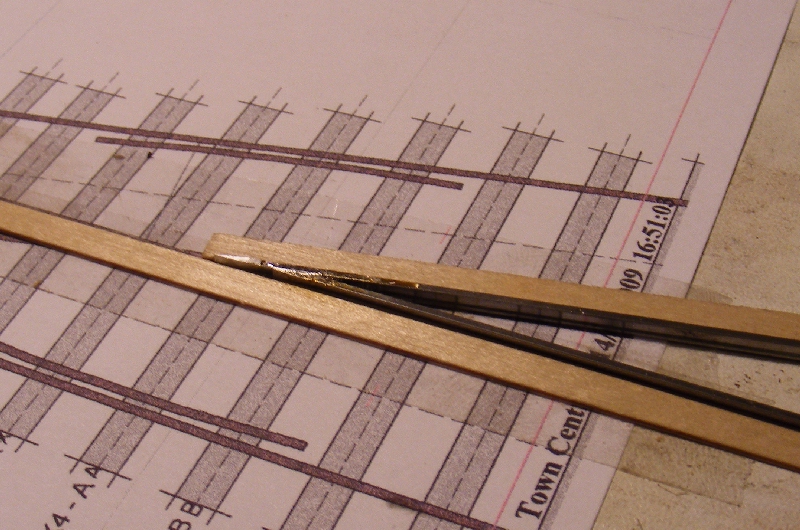

The rails are first tried in place in the jig and when satisfied

with the fit removed and replaced with a dab of solder paste in the

joint.

|

When

finished you want the point rail to be in the normal, or main road, the

splice rail in the diverging road. It appears to be the other way round

in the photos because I always solder my vees with the head down and

held by the double sided tape. This ensures that the running surfaces

are held properly by the jig and keeps any tape residue off the bottom

surface which needs to be clean for soldering to the rivets. A touch

with the iron will melt the solder paste and give a good joint.

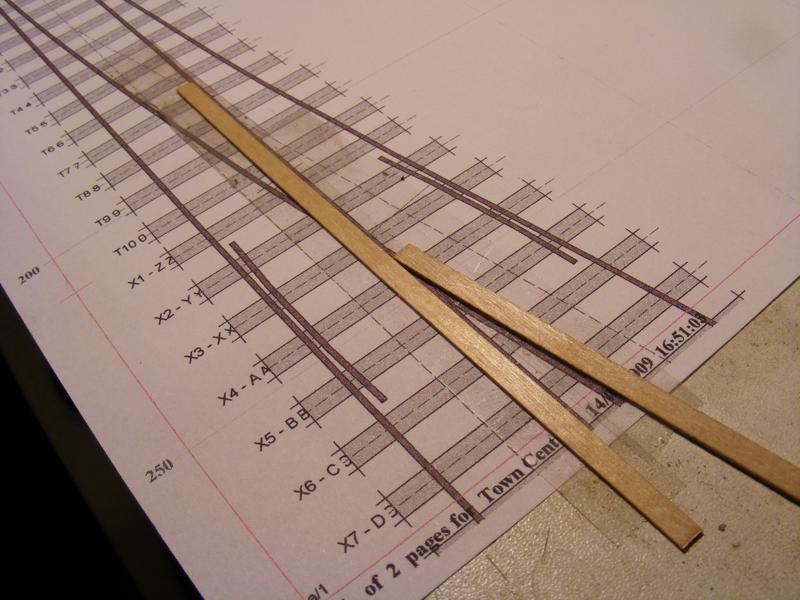

Preparing timbers

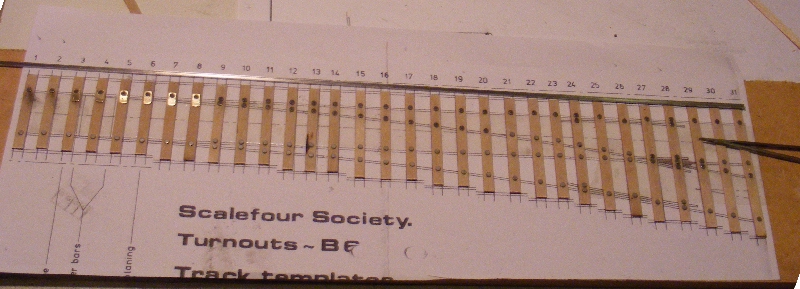

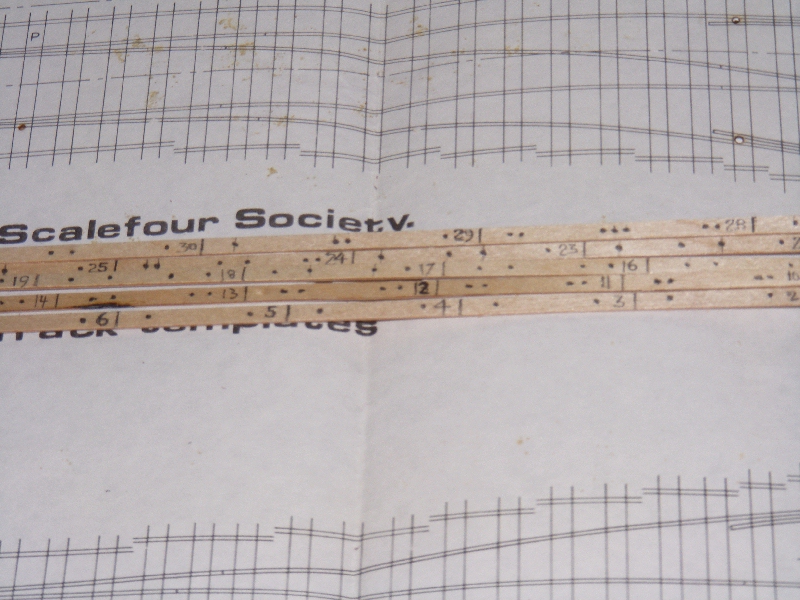

Note

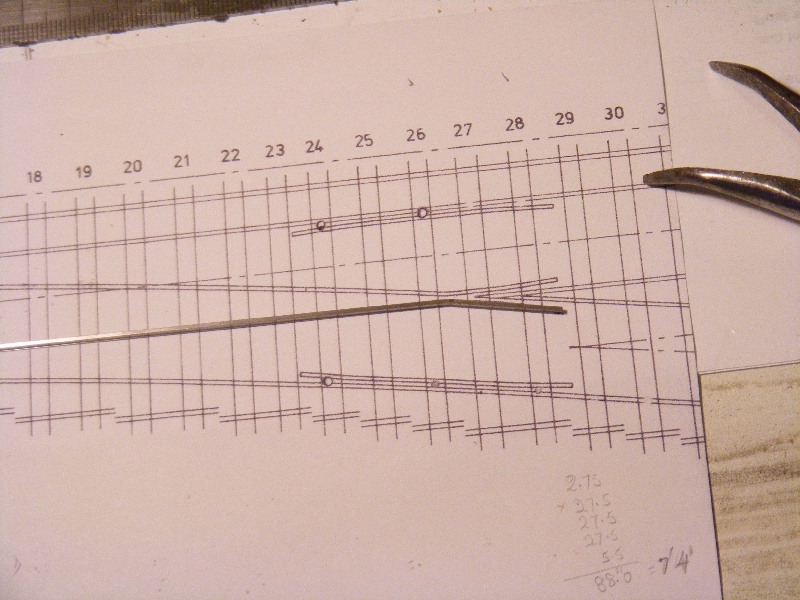

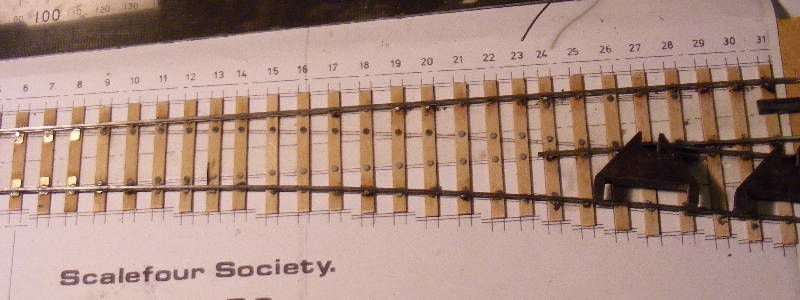

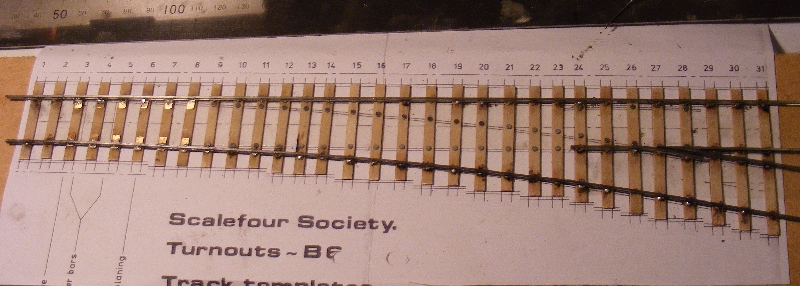

I am using a different template here, I decided to use an old Scalefour

society template to show that its not essential to have "Templot"

I always mark out all the timbers on the 12" strips and complete

all the punch and rivet work before cuttng the strips to length. This

minimises waste, if you start marking out from the crossing end and

work towards the toe, then when the next timber no longer fits you

should be able to fit one of the shorter ones at the end of that strip.

Mark the ends of each timber, its number and a dot where each rivet

needs to be. The original P4 templates have dots to show you where,

"Templot" provides a timber centreline, with these old Scalefour

templates you need to estimate or mark where the rails intersect the

centreline of the timber.

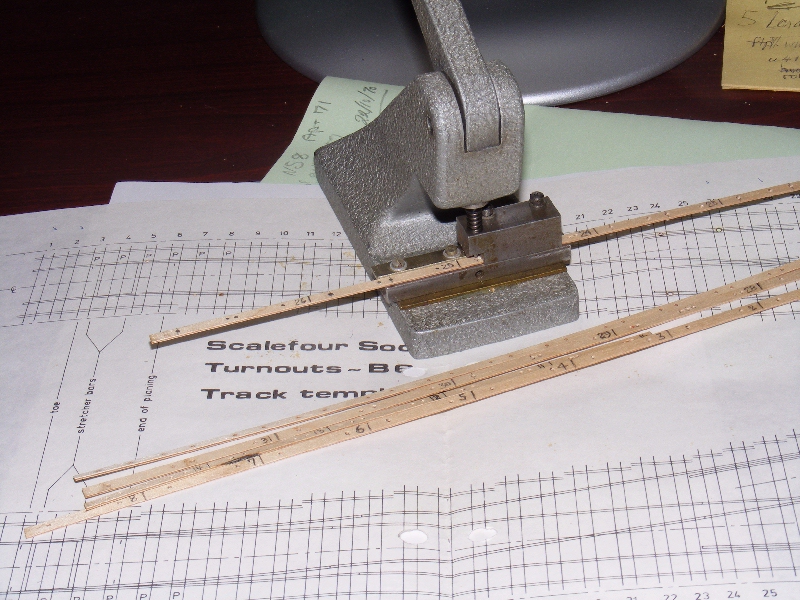

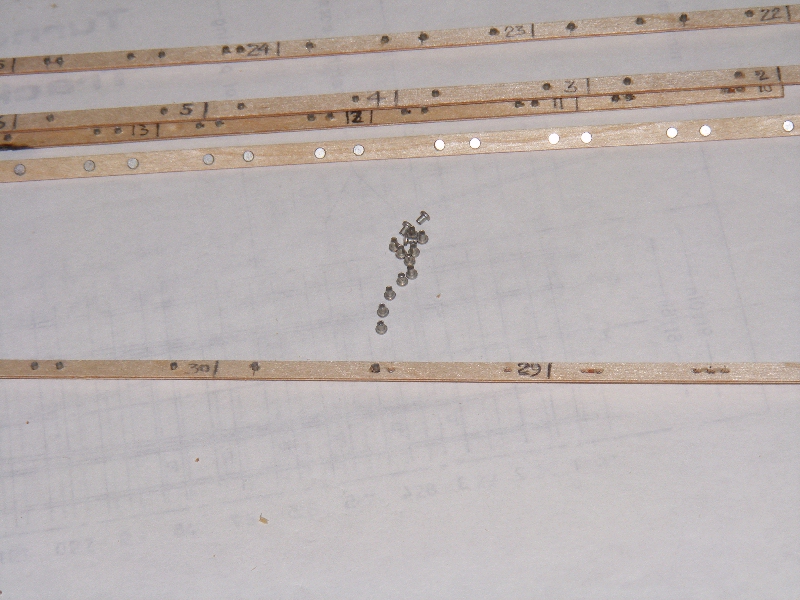

The strips are now run through the punch making a neat hole for each rivet position.

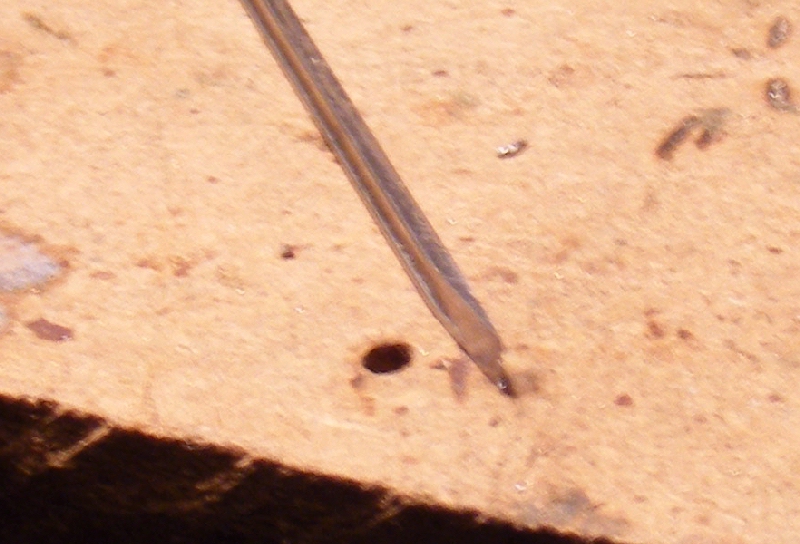

Then

loaded with rivets, keep the rivet heads on the unmarked side to make

sure all the markings end up underneath the turnout. Use the end of the

strips to tease out a line of rivets and persuade them to stand up

nicely, then work along the line of rivets putting a hole over each

one, with a good light and a bit of practice you soon get the hang of

it. If you find this difficult a scriber can be used to help the

alignment by putting the point down through the hole and the tip into

the end of the rivet.

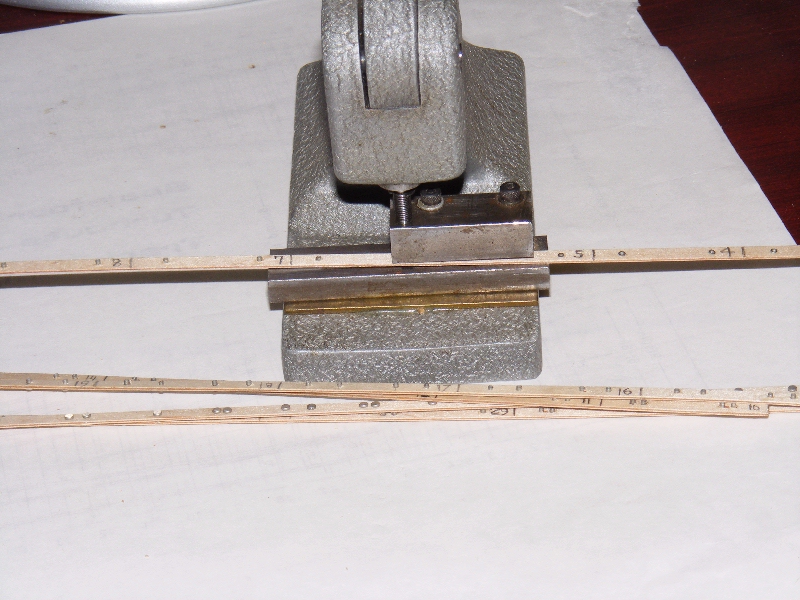

Once loaded the final job is to run the strips through the press tool.

|

Assembling the Turnout

|

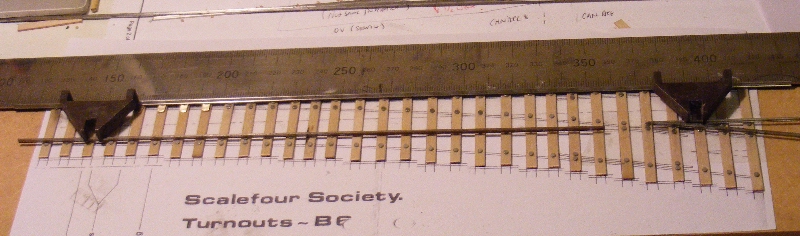

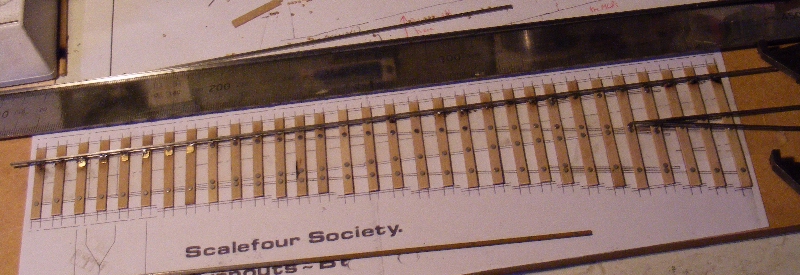

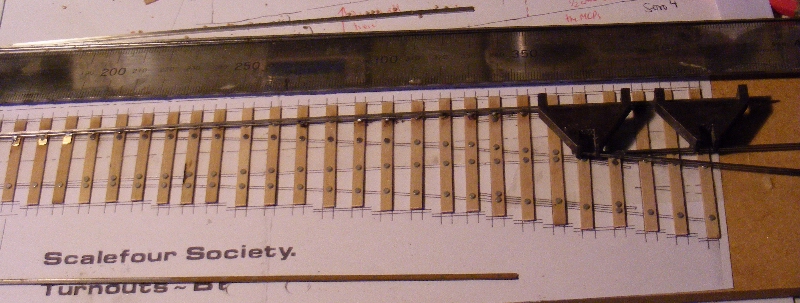

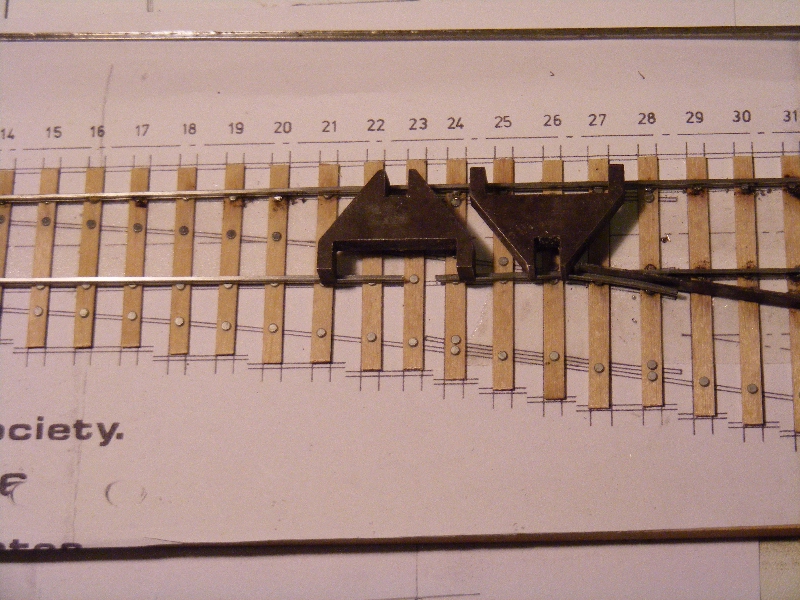

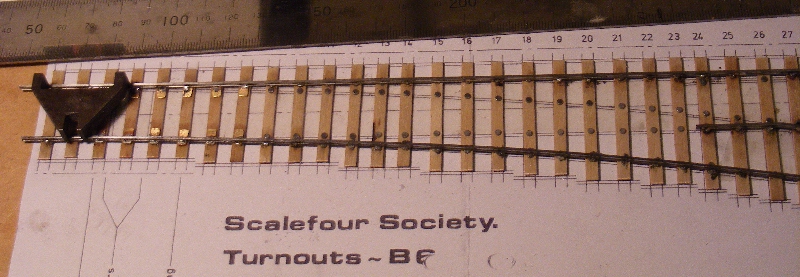

The timbers are cut to length and stuck to the template with

double sided tape, here the vee and straight stockrail are ready for

fitting and a set of Bill Bedford slide plates have been prepared for

the straight stockrail. The Bill Bedford plates are available from Scalefour stores as item 165, or from Eileen's emporium.

Here

the rails are held in place with a pair of track gauges to confirm fit.

A steel rule is used to keep the straight stockrail straight. A spare

piece of rail is used to keep the left hand gauge level.

Don't worry if you only have one track gauge, you can manage perfectly

well with one and most of my track was built that way, but a

second set does help and a chance find at the Scaleforum bring and buy

provided mine.

When ready the rails are temporarily removed, the rivets and rail foot

cleaned up with a fibreglass brush, a dab of solder paste put on each

rivet, the rails put back in place and the stock rail soldered.

The vee is then carefully positioned, with one (or two) gauges and also soldered in place.

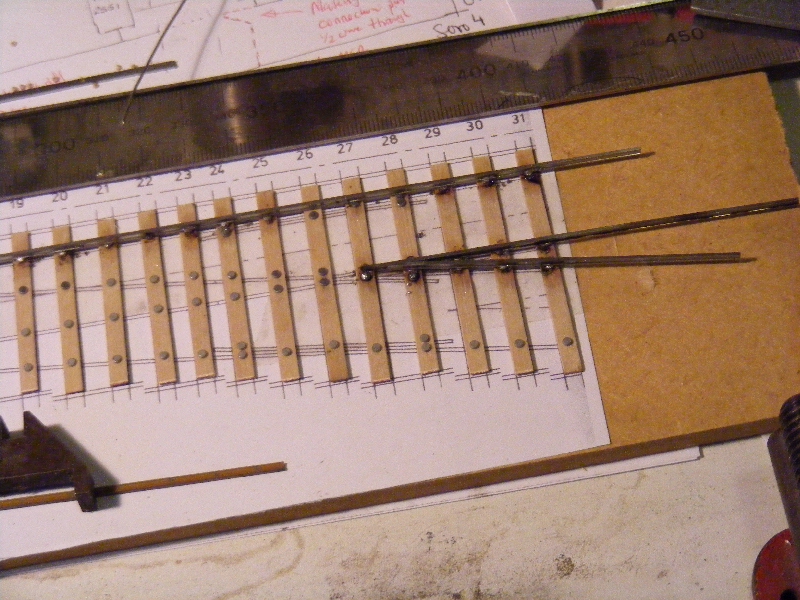

The next task is to prepare the straight wing rail, an unused template is used to check that the bends are to the correct angle.

Once happy with the bends the rail is cut to length.

The

wing rail is held in place by track gauges and a crossing flangeway

gauge and soldered. Use the steel rule, or a block gauge if you have

one to confirm that the alignment from wing to nose is straight, take

it off and repeat if any error found as alignment here is important for

good running.

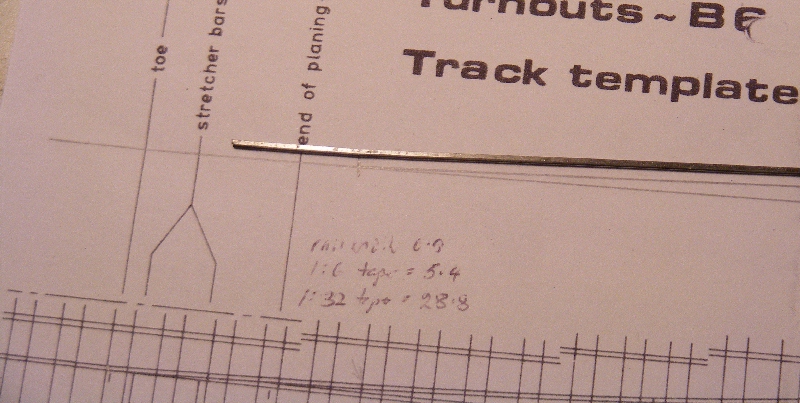

Next

job is to prepare and fit the curved stock rail, this rail has a set

just before the blade toe so that the initial angle of divergence is

the same as the planing angle of the blades, important for a good fit

of the blades without any gauge narrowing. Its difficult to judge this

accurately from the template due to the curve in the rail so I find it

better to draw the angle as shown here. In this case the planing angle

is 1:32. The rail complete with set is shown next to the drawn angle,

it doesn't look much but its important to get it right. (Note I have

also calculated the planing lengths for both the vee rails (6*0.9 =

5.4) and the blade (32*0.9 = 28.8)).

The

stock rail is held by one gauge on the straight portion at the toe and

the rail curved between finger and thumb to fit the template, note that

the planing length (as calculated above) should remain straight to fit

the blade. Once happy with the curve solder in place, don't forget the

slide chair plates. Start at the toe where the rail is held by the

gauge, and the straight section over the planing length, then transfer

the gauge to hold the stock rail to gauge from the previously soldered

vee and complete the soldering.

Holding the steel rule against the straight planing length shows up the set clearly.

Its now beginning to look like a turnout.

|